Fixed my error and I’m getting my 5V on the GPIO 5V pin. Still don’t know if I damaged anything. I very likely did though. Did a quick run and got 4.8 V on my explorer pHat motor terminals. Still doesn’t want to turn though. Its definitely moving faster in forward and revers. Almost turns, it tries but then the motors stall. I’d say I damaged the explorer pHat.

So guys, it looks like it my error all alone. Thanks for all the help anyway.

1 Like

Just ordered a new Pi zero W and Explorer pHat. I have to say though, I’m not liking these micro motors and wheels very much. The wheels keep falling off, the shafts are IMHO way too short. They might just barely go half way though the wheel hub. That means they only mate to one of the center pieces. Anyway, they will stay until I see if I can get it all working. If it runs and turns Ok, I’ll then try my original motors and wheels. Those ones are splined, go on tight, and are locked on with a screw. I really really want to get this working and usable.

It’s possible they’re holdouts from the batch of loose ones we had :( you should drop us a support email for replacements, just to be sure!

Longer shafts is something we may be able to do, I’ve passed that on.

OK, didn’t know about the loose ones? I do seem to remember a seeing similar complaint back when I first signed up to the forum. Something else that was weird is there were four extra orange center bits in the pack? The wheels were pre assembled, was I supposed to swap out these center bits? These are the part that goes on the axel shaft?

Aha! I’m told that changing the bits would have been a monumental effort, so we packed fixed ones along with the loose ones! That makes sense. If you swap 'em out, your wheels should stay in place.

I just swapped them out and they do appear to go on tight now. Thanks. I don’t remember seeing any thing advising to change them out? But to be honest, being pre assembled, I didn’t look all that closely at the packaging.

I put two knitting needles thought two opposite holes to align the two wheel halves up, then put the rubber tread back on. Making sure to get the two center holes orientated the same way.

My motor covers are making the shafts just that little bit shorter, which made things that much worse. I think I’m OK now though. Won’t know for sure until I get it running. It’s all striped down waiting for the new parts t arrive…

Good news and bad news. Soldered up my new Explorer pHat and Pi Zero W and did a quick test using a 2.5A power supply and it turned Ok on a smooth surface. Stalled out on a carpet though. Put the power boost and battery back in and its back to not turning again. Just a tiny jerk moment and the motors stall out. Unplugged the power boost and plugged the power supply back in, same deal, stalls out. Removed the battery and it turns Ok. One step forward two steps back. Looks like I’ll have to get a smaller lighter battery?

Picked up a couple of 2000MAH power packs at Staples. Were on sale for 4 bucks each. Up to 1A out. I strapped one to my Rover and ran it around a bit. It turns now, but things still aren’t 100% functional. I can see one wheel stalling and its struggling a bit to turn on the kitchen floor. Won’t turn at all on the living room carpet. At least now I know a smaller lighter battery is the way to go. Still not happy with the performance though. This is one project that’s fought me all the way through. I’m beginning to wonder if it will ever work the way I want it too? I’m thinking I may have to swap out the PowerBoost for the 2A out https://shop.pimoroni.com/products/mp2636-power-booster-charger-module and a small battery.

What are people using with the official Coretec ‘Tiny 4WD’ Robot Rover

I’m just about ready to abandon this project and sell the parts. Or make two two wheel drive robots.

Another potential approach might be to try an H-bridge driver that can accept and supply ~6v to the motors. There’s definitely a power-to-weight challenge.

If you look at the Tiny4WD here, you can see it’s running from a really, really small LiPo batetry: https://www.youtube.com/watch?v=eh4GcPFB2xY

I also wonder if you’ve damaged your motors from all this experimentation. It could be the things you’re trying now are failing because the windings have been damaged from overheating.

I have no idea what’s going on to be honest? The last batch of motors I ordered, the ones used in your kit, are hardly used. Two or three test runs. My current plan is to order two more of the rover chassis from Adafruit and build two, two wheel drive rovers from the motors I bought before. The ones that fit that chassis without any modification. The original explorer pHat and Pi Zero, last time I tried them, drive two of those motors no problem. I now have a second explorer pHat and Pi Zero to build a second two wheel rover. I just need to order a couple of the mini hack3r boards to hook everything up. The Pi’s have female headers going out the bottom. The power packs I just bought will run those no problem. I’ll just give them to my grand kids to play with and be done with them. The new motors, I’m not sure what I’ll do with them? Maybe like you say, get a different motor driver board that uses a higher voltage.

I do appreciate everybody’s input and help. This has just been a very frustrating project. It’s fought me all the way through. It’s not often that I give up on a project but this may just end being one of those.

Just received some new parts to start phase two and make use of some of the stuff I bought originally.

All my new build pictures are here,

https://1drv.ms/f/s!AjOYwiwlwDtpgrNitzE9mWKSbll5jg

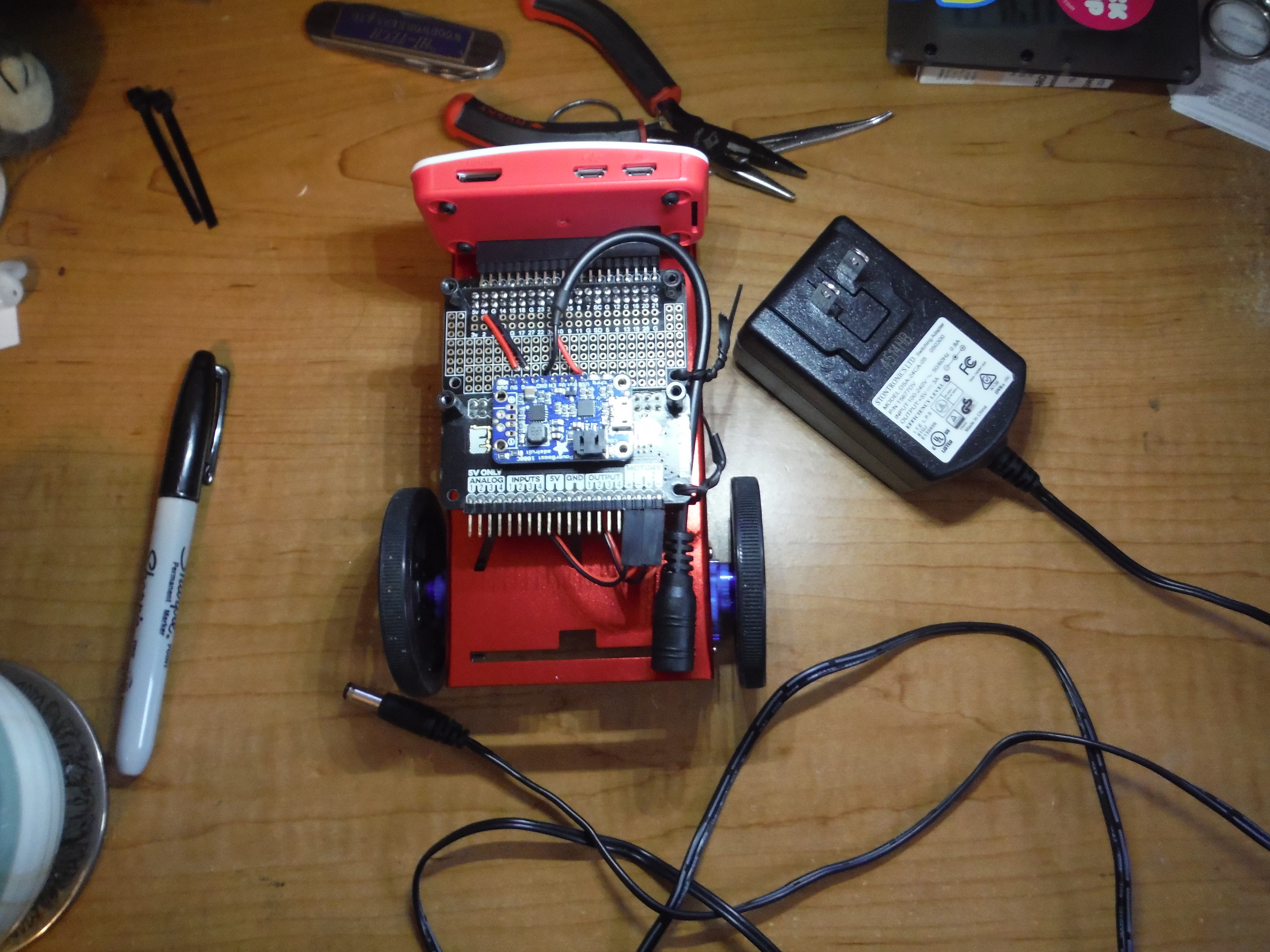

Two Zero W’s mounted on a two Mini Black Hack3r boards each with an Explorer pHat and ProtoZero. I plan on mounting a PowerBoost 1000c to the ProtoZero with an on off switch (enable) for the PowerBoost and a Shut Down button for the Pi. The 2200 MAH battery will be mounted right over the rear wheels. Had to move the caster from its original position farther forward. It’s now right under the Pi Zero. It makes the Rover less tippy when it goes over bumps etc. The tippy issue was my main reason for trying to go to four wheel drive. It now has a longer wheelbase. still a work in progress though.

Looking good.

Ihave built a couple of 2 wheel drive buggies in the past and the caster tends to make the steering a little skittish. I built a 4 wheel drive buggy which was a lot easier to steer and drive but the load was quite high and battery life was short.

I don’t like the caster all that much but I had all kinds of spare parts kicking around from my attempt to do a 4 wheeler. $ wheels, 4 motors, a couple of spare Explorer pHats, spare Zero W’s, etc. I just needed the chassis and casters. The motors I had are in servo bodies and mount in those chassis easily. It was made for them specifically. I modified where the caster mounted, I moved it farther forward. It’s now right under the Pi Zero.

Today I mounted my PowerBoost’s to the Proto Zero’s. And added my own barrel connector power cables.

I originally started withy this kit, https://www.adafruit.com/product/2939 Then bought 2 more motors and 2 more wheels. Then I had the issues I posted above in the original post. Then I bought 4 of the micro motors from Pimoroni and still had issues with it not wanting to turn correctly. Not wanting to waist the 4 original motors and wheels I bought just the replacement chassis. I cut the original one to fit the micro motors.

I’ll have another go at the 4 wheel one that’s not working at some point. I have bit of work left to finish with these new ones first. I have to mount and hook up the battery. Then figure out how I’m going to control it. I originally used a wireless keyboard, this Time I’m going to try using a Bluetooth controller that has a nice thumb stick. That’s the plan anyway.

I have used Bluedot on an android phone to control a buggy, it workd quite well.

I may give that a look see too, thanks.

I have a new plan for my 4 wheel rover. I’m going to convert it to a tracked vehicle. With this,

I’ll have to adjust my wheelbase slightly 1/2 a centimetre or so. I’ll try it with 4 motors at first, no idler wheels. I have no way to attach the idlers anyway with my current chassis. Those wheels should fit my motors, I have the micro gear motors.

Now I just have to convince my better half to let me spend more money on this lol. This rover I want to run outside on grass etc so I really hope this works. Going back to two wheel drive would mean buying yet another chassis. I’ll do it if I have too but I’d like to reuse what I have now.

What started out as one rover has turned into three. The grand kids are having fun with the other ones so it has worked out OK in the end. I just have the bits for the original 4 wheel sitting on the shelf gathering dust.

Got the track kit. Can’t use 4 motors as two of the gears or wheels are free wheeling. No big deal two motors is fine by me as long as it works. Looks like I have at least one bad motor. Left side stalls way too easy. Swapped out the explorer phat and Pi from one of my two wheel drive rovers and same deal.

And the swapped parts work fine in the two wheel drive rover, so it must be the motor.

The two wheel drive rover has the wheels and motors from this kit.

Those ones are really hard to stall while the micro gear motors are fairly easy to stall? My motors are mounted in the motor cases / covers. Will have to tear it all down to get at them and swap one out. I have 4 so I’ll swap in one of my two spares and see how it goes.

The two two wheel rovers are working great, just not so good for using outside as they tip easily. The struggle continues. =(

Stalling on one side only? it’s not the motor, with no tracks on they both spin at the same speed and both require the same pressure to stall them. Also, reversing the motor connections on the explorer pHat left to right (swapping the motor 1 and motor 2) makes no difference. It’s only with the track on that it stalls?

Checked and double checked its 85 mm between wheel centers. Also checked and double checked the alignment (center line) of both sides to be sure the track is straight? and that the idler is straight. Tracks aren’t rubbing on anything. I’m at a lose as to why this won’t work. With the track off the idler spins nice a free. Put the track back on a very light finger pressure stalls that side?

Wheels and idler are on as per the pictures with the washer in the correct place.